PRE ENGINEERED BUILDING COMPONENTS

PRIMARY FRAMING MEMBERS –

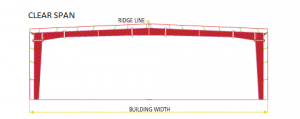

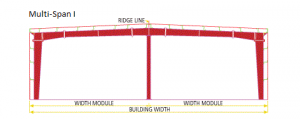

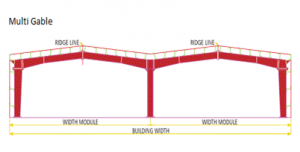

Primary built–up members (H-Beams) are manufactured by gas cutting of HR steel plates in required sizes, standards confirming to ASTM A572 Grade 345 Mpa. These plates of various sizes are welded together on one side by continuous welding and other side by stitch welding at regular intervals to make an H-beam.

These are custom-built sections, so virtually any size of section can be made as per design requirement. Splice plates are welded at the end of different H – beam sections. These H-beam sections are assembled together by bolting the splice plates to make a complete frame assembly.

The Primary members are available in high grade steel of minimum yield strength of 345 Mpa.

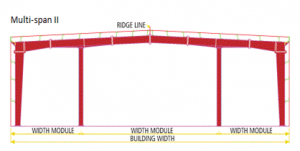

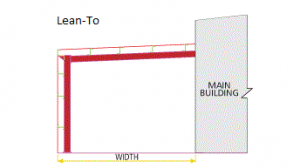

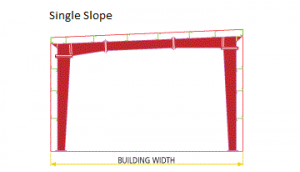

Pre Engineered Buildings are designed with the help of International Standards. These are precisely manufactured as per customer’s requirement and also can be fitted with different structural accessories including mezzanines, Canopies, Fascia, Partitions, crane beams etc. to enhance the building usage and its Aesthetics.

SECONDARY MEMBERS

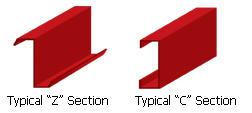

Purlins, girts and eave struts are secondary structural members used to support the wall and roof panels. Purlins are used on the roof; girts are used on the walls and eave struts are used at the intersection of the sidewall and the roof.

Secondary members have two other functions:

- Act as struts that help in resisting part of the longitudinal loads that are applied on thebuilding such as wind and earthquake loads .

- Provide lateral bracing to the compression flanges of the main frame members therebyincreasing frame capacity.

Purlins, girts and eave struts are available in high grade steel of minimum yield strength of 345 MPa in 1.5 mm to 2.5 mm thicknesses. These members come with a pre-galvanized finish or with a coat of Zn chromate primer for corrosion protection.

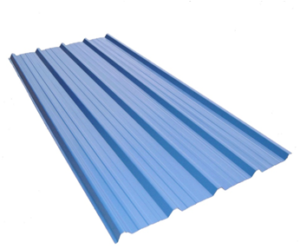

ROOFING AND WALL CLADDING

Apax Buiding Systems offer Roofing and Wall Cladding Panels of 0.5 mm thick and 550 Mpa Galvalume material. Standard roof panels are made of Bare Galvalume material and Wall Cladding panels are of colour coated Galvalume material. Panel paint film thickness is 25 microns on the exterior weather face and 5-7 microns of PU compatible epoxy primer on the interior face.

The sheeting material is with hot dip Metallic coating of Galvalume 150 gm/m2 total, AZ 150 as per ASTM A792 or AS 1392, and wall coated with 25 microns regular modified polyester paint system applied on Zincalume.

Apax Building Systems offers a choice of different -2 colours in wall cladding panels. These Roofing and wall cladding panels have excellent corrosion and weather resistance longer spanning capability, Thermal Efficiency, Long Durability & Safety.

- COMPANY PRESENTATION

how can we help you?

Contact us at the Apax Building System office nearest to you or submit a business inquiry online.